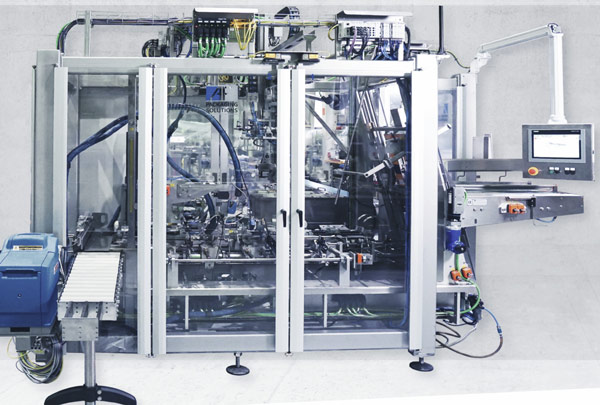

Packer with Delta Robots

FlexLine

Optimise sticks handling with the A+F FlexLine, our packer with Delta robots and 3D movements. You want to convert existing systems? This can be done quickly and reliably using accurate format kits. Benefit from reduced operating costs thanks to low-maintenance design – and ensure a reliable and gentle pickup an placement of your sticks, including reject ejection.

A+F FlexLine in detail

Benefits

- Quick, reliable conversion through the use of precisely fitting format sets

- Low operating costs due to high-quality, low-maintenance design

- Before delivery, the A+F FlexiLine is run in with original sample material and undergoes a documented final inspection

Technical details

- Sticks packed in foil 4 x individually cut or 2 x uncut as groups of 2 contiguously or 1 x uncut as a group of 4 contiguously

- Stick parameters: 235mm x 45mm x 10mm (LxWxH); 12g

- Capacity: 12,000 sticks / hour with flexpicker Cycle time: 1.2 seconds

- Control: Schneider Electric

Schneider Electric servo motors

HMI Siemens TP 1200 Comfort

Functional description

- Stick feeding 4 x individually, 2 x as a group of 2 or 1 x as a group of 4 together, on transport system technology

- Recognition of the sticks in the A+F system by sensors

- Ejection of faulty sticks in case of signal from the filling machine

- Picking up the sticks and placing them in stacking tray 1

Stacking the sticks according to the packing format - Procedure stacking chute 1

Removal of the stacked sticks from the stacking chute and placement in the prefolded wraparound carton

While stacking chute 1 is in the removal position in front of the carton line, stacking chute 2 is loaded by the flexpicker

Select your language